EDGECAM

✓ CAD Neutral

✓ Easy to use

✓ Complex Machine Support

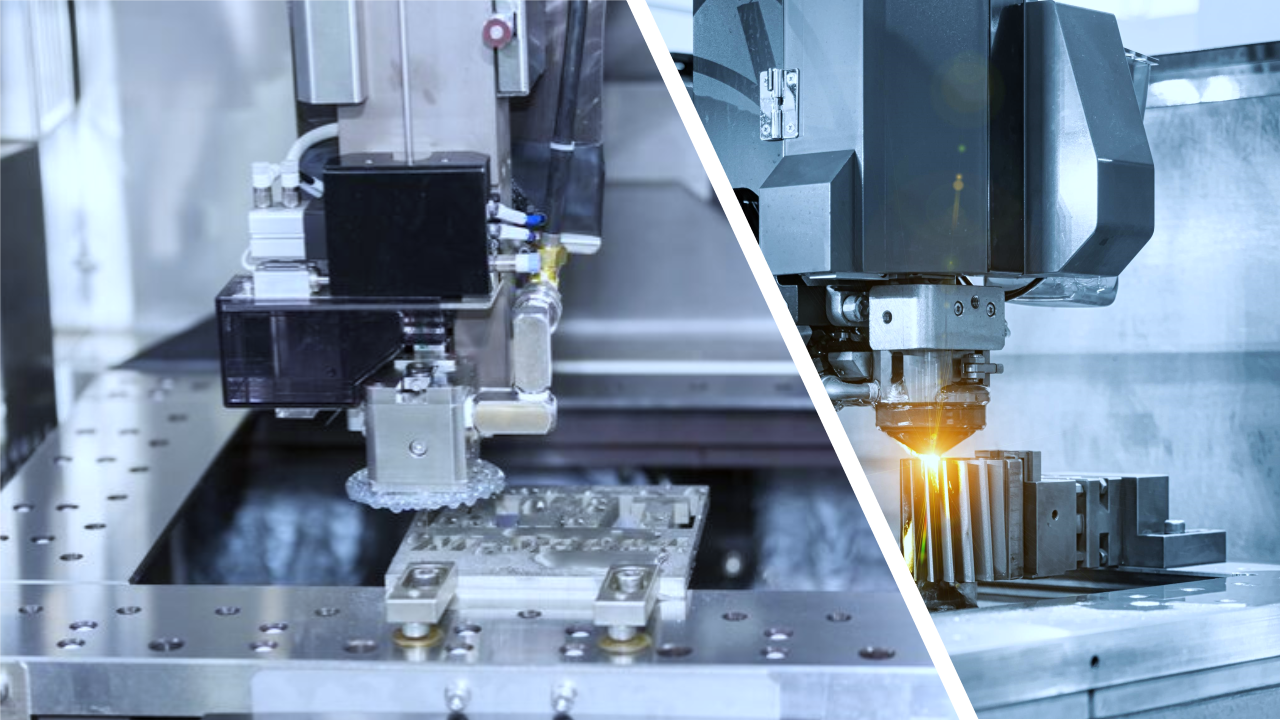

✓ Wire EDM

✓ Hybrid Manufacturing

✓ Production programming

✓ Probing and Inspection

Features at a Glance

Features at a Glance

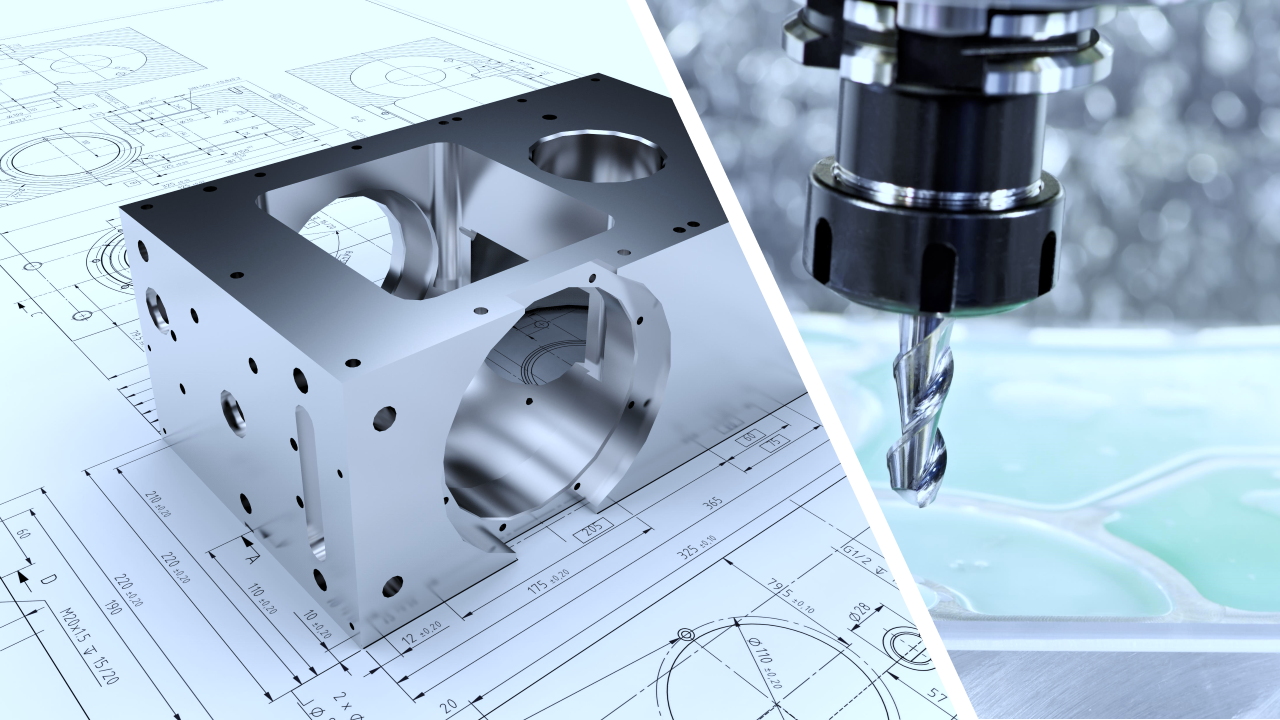

Edgecam seamlessly Integrates with mainstream CAD Software such as Solidworks, Autodesk Inventor, Solid Edge, Creo to name but a few, whilst offering users an easy to use Graphical interface and intuitive dialogues making programming simple for first time users with full control for more advanced tool path requirements.

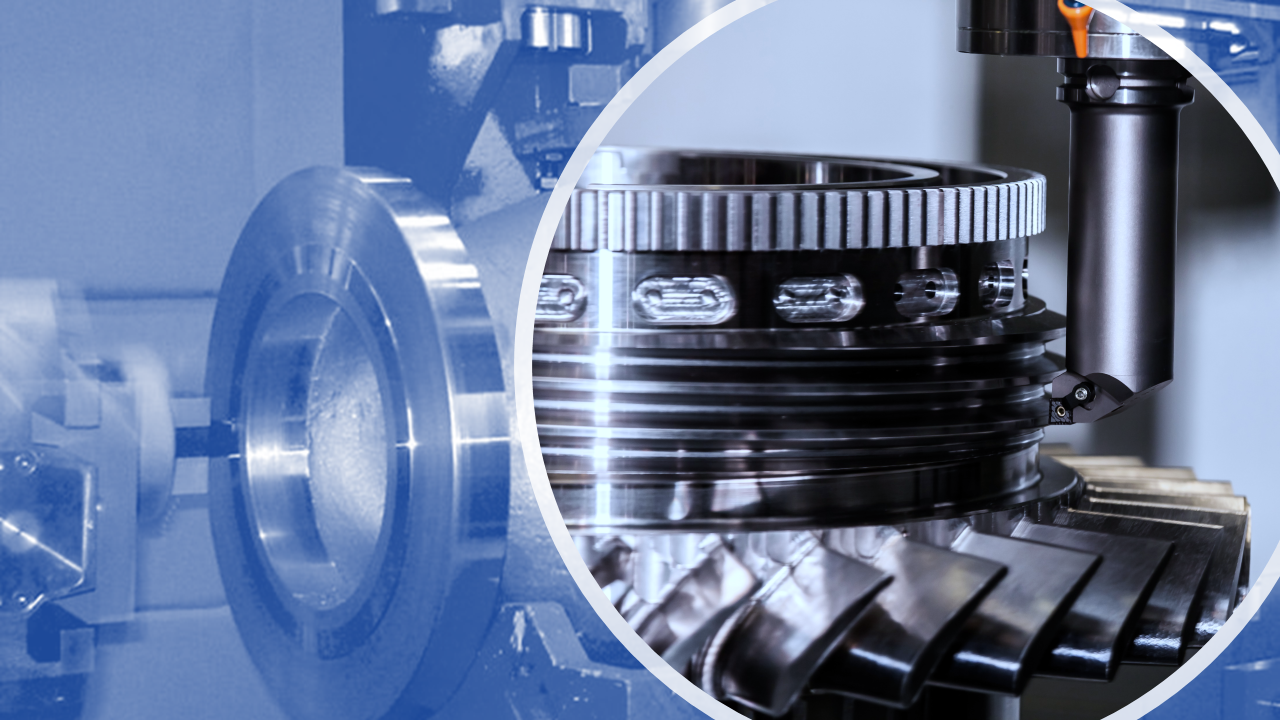

Comprehensive 2.5 Axis to full 5 Axis Simultaneous Milling is fully Supported.

Complex Mill/Turn Components and Machine Tools are taken care of with ease with full support from 2 Axis Turning to Advanced Multiple Turret, B Axis and twin Spindle Support. Edgecam’s Wire EDM CAM solution provides you with the flexibility and confidence to manufacture 2 and 4 axis parts accurately and efficiently. Complete the process with on-Machine measuring using Edgecam Probing and Inspection functionality.

A range of Standard Edgecam options available:

– Multiple setups for different machining operations easily taken care on the same machine tool or between different machining disciplines.

– Automatic Feeds and Speeds Calculation with comprehensive Tooling libraries supplied as standard.

– Eliminate “fresh air cutting”. Edgecam recognises the latest stock condition after each machining process, only machining areas where stock from previous un-machined areas is necessary.

– Full Machine Simulation and Collision detection

– Automate Programming using Edgecam PCI Macro’s and templates or utilize Edgecam’s Knowledge based manufacturing strategies for 3D Solids based programming

– Shopfloor documentation of the operation process is automatically created along with tooling kit/list.

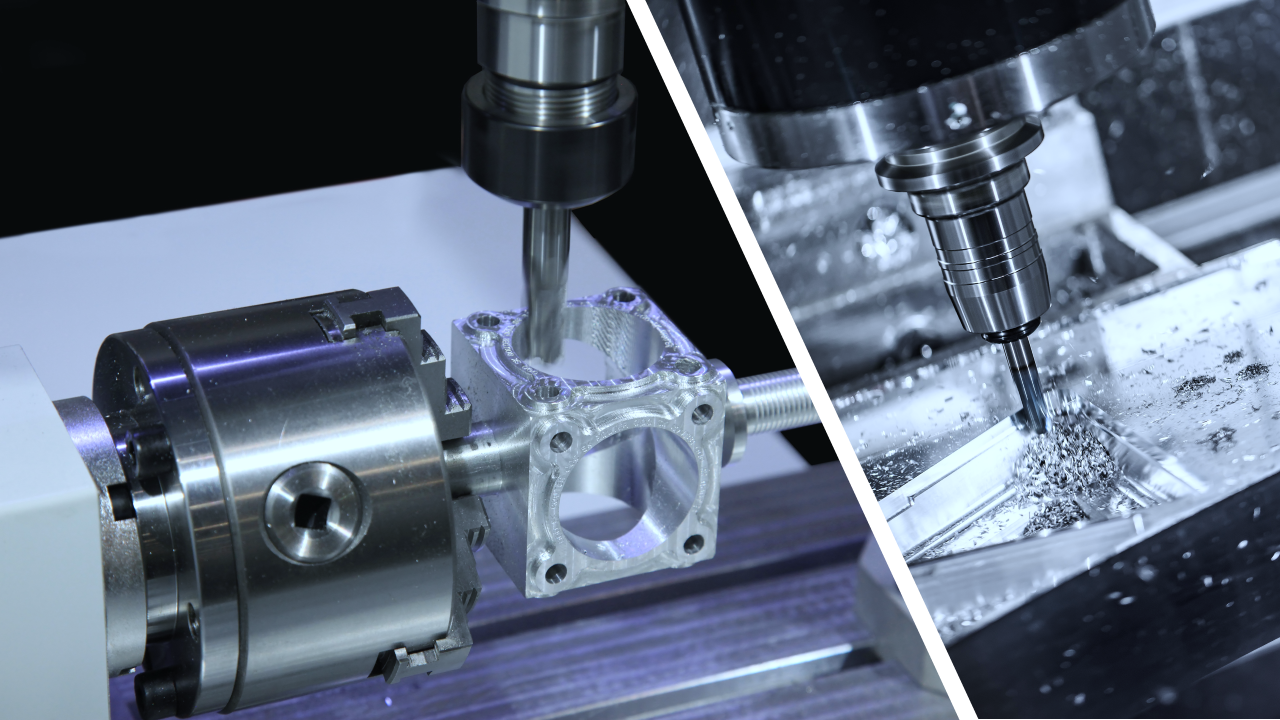

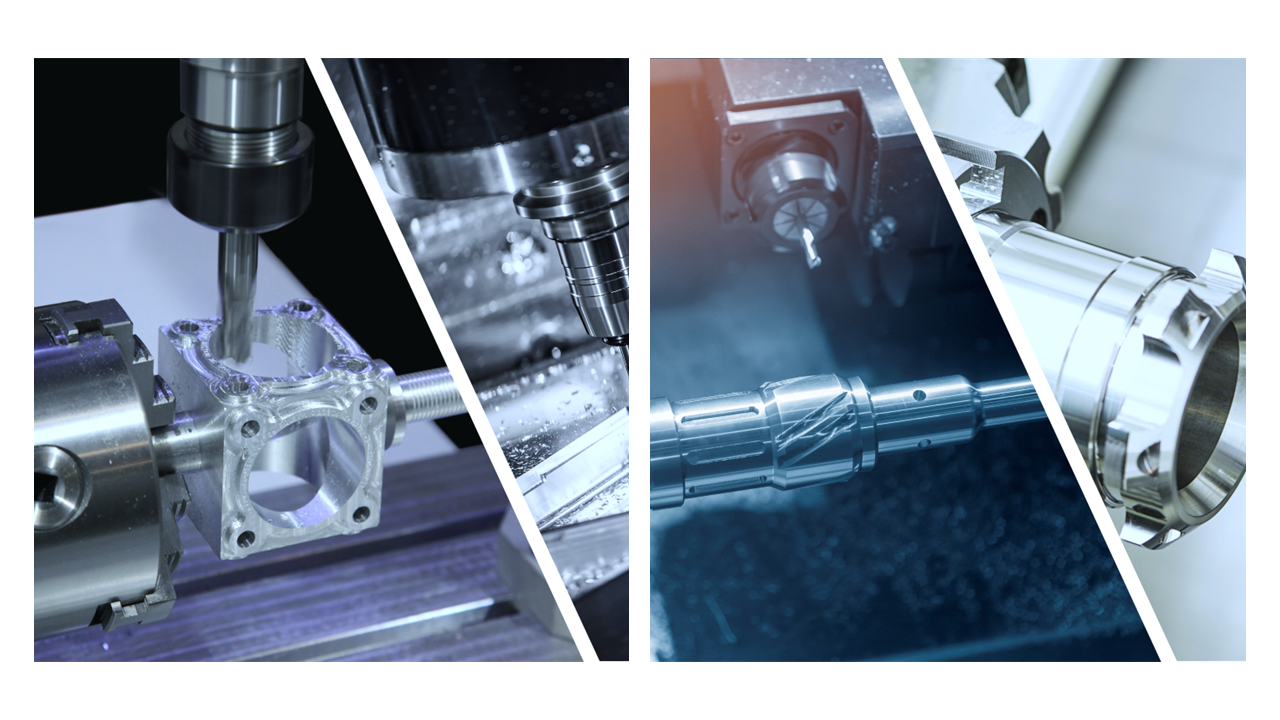

Milling

Essential Milling

2.5 axis Milling

Suitable for Companies with 3 axis Machining centres but the components being manufactured do not require full 3 axis CNC milling functionality. Edgecam has a wide range of milling and drilling options available to get those parts programmed fast. Visualise the complete machining process in Edgecam CAM Simulator with full machine simulation. Have peace of mind to get the part machined efficiently, while saving on setup time and tooling costs.

Edgecam Standard Milling

Full 3 axis with 4th axis Rotary and positional and 5 axis Positional capability.

Suitable for Vertical or Horizontal 4 or 5 Axis Machining Centres. This is the most popular Edgecam module to get the most out of you Machine Tool from the get go. With a full suite of Hole options available, Edgecam’s efficient Waveform Roughing Strategies and 3 axis finishing toolpaths, Edgecam exploits the productivity of single setups on 4/5 axis CNC machines.

Edgecam Advanced Milling

Support for Angled head attachments and Secondary Z/ Quill Axis

Adding to the 3 axis capability of Standard CNC Milling module, Edgecam Advanced CNC milling Includes support for Deep Hole Drilling, Plunge Roughing and opens up a broader range of 3 axis Surface / free-form finishing toolpaths. Adding to this, more advanced machine configurations are supported such as Angle head Attachments and Quill axis.

Edgecam Ultimate Milling

Complete suite of Edgecam Surface finishing Toolpaths

Building on the functionality and capability of the Advanced CNC Milling Module, open up the complete suite of Edgecams excellent Mold & Die 3 axis finishing Cycles to achieve Optimum surface finish on freeform components.

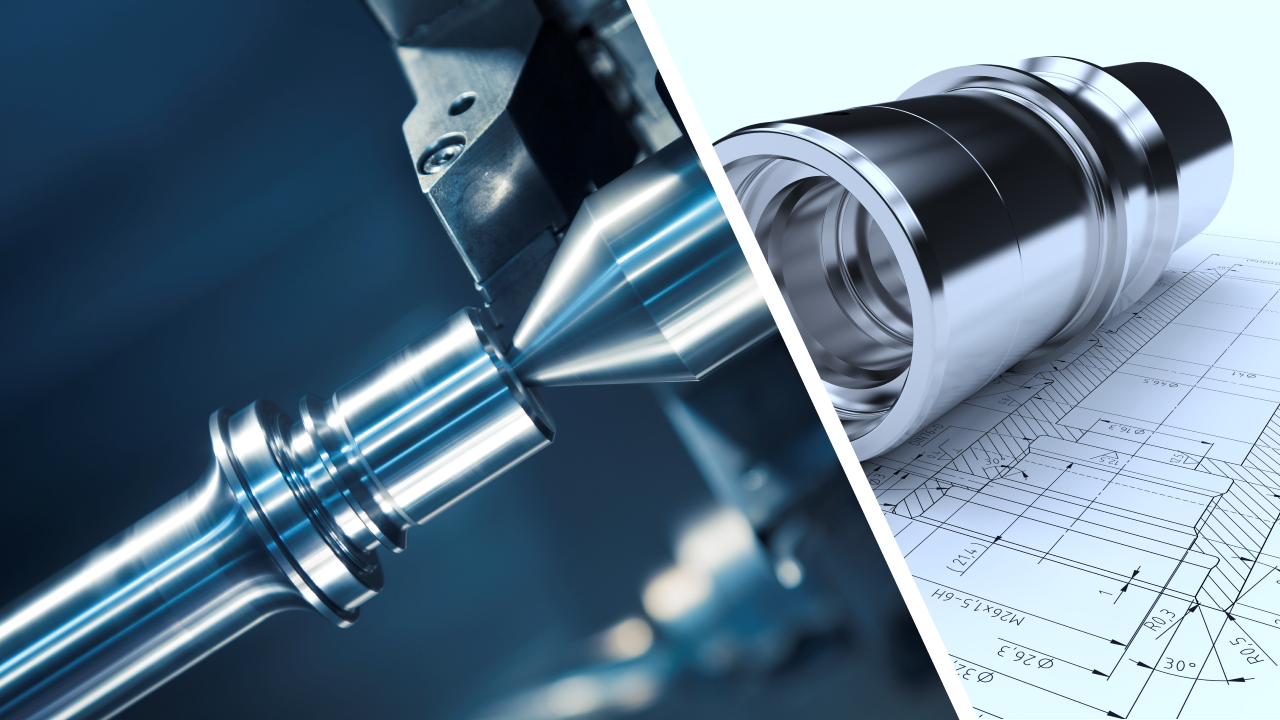

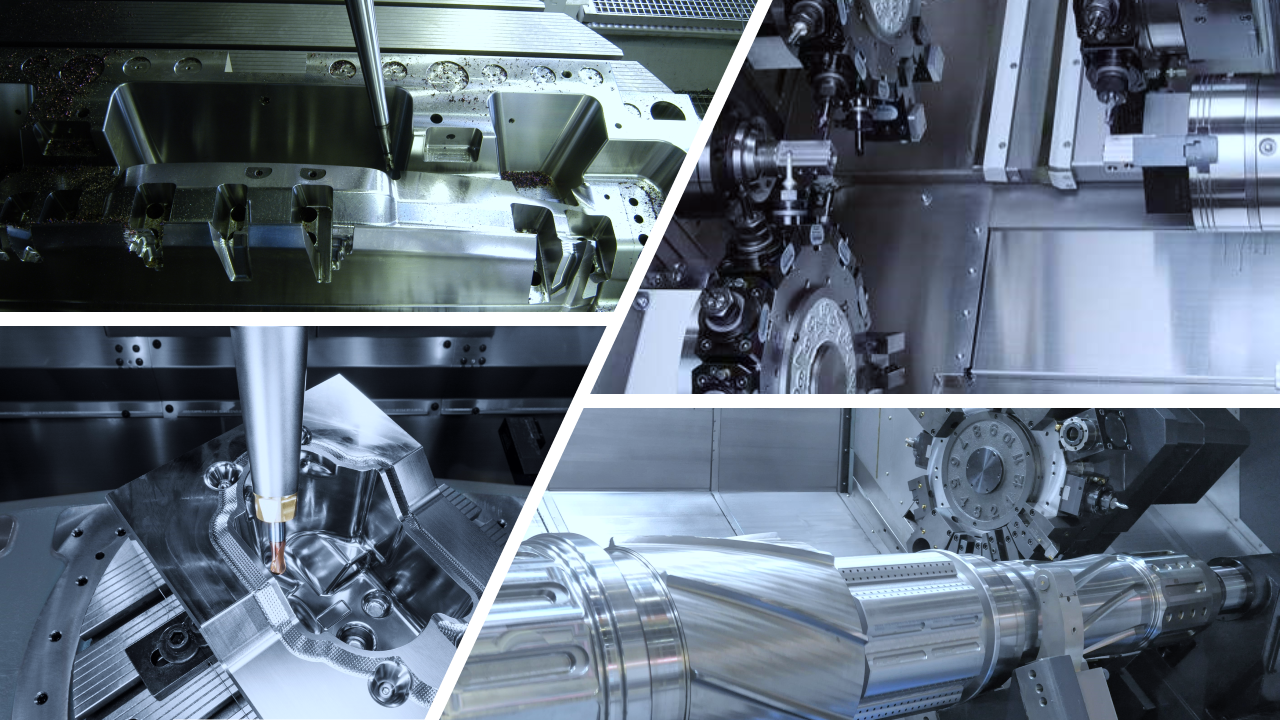

Turning

Essential CNC Lathe

2 Axis Turning

Suitable for 2 Axis Vertical or Horizontal CNC Lathes with a Single Turret and Single Spindle. Tailstock and steady rest support with support for all Tool Types. Advanced Functionality for all 2 axis Turning applications whether they are large or small components, Hard or Soft materials. With Edgecam Essential CNC Lathe you have complete control over the production process. With full machine Simulation in Edgecam CAM Simulator, avoid unwanted collisions and Setup time.

Edgecam Standard CNC Lathe

2 axis CNC Lathe with CY axis Milling Capability

This module will suite Vertical or Horizontal CNC Lathe Centres, Single Spindle and Single Turret Machines with Live Tooling / Milling Capability. Machine those components you have never been able too because of limited programming capability at the machine Control. Edgecams Standard CNC Lathe Module will offer capability to machine complex Components with advanced and efficient toolpaths including Edgecam Waveform Turning technology, saving you machine time, setup time and Tooling Costs.

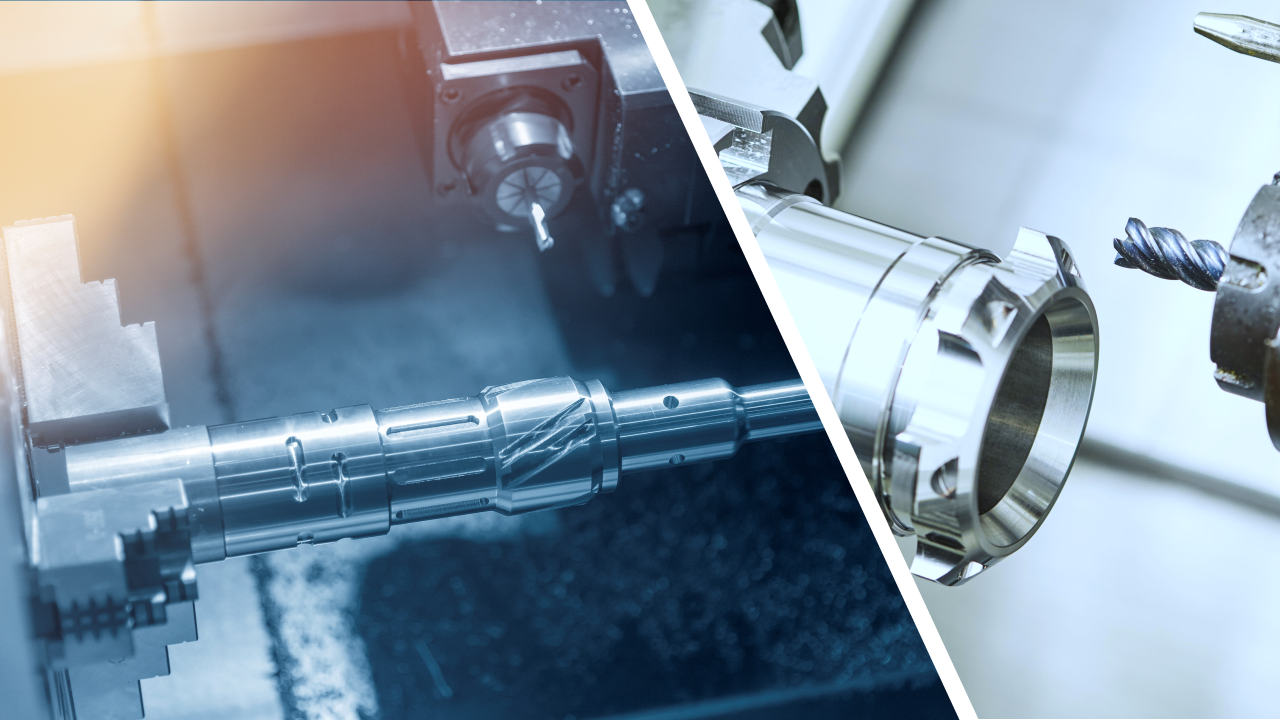

Edgecam Advanced CNC Lathe

Suitable for Turn/Mill Multi-Task Machine Tools. Support for Twin Turret, Single or twin Spindle CNC Machines. Machines with B axis Capability is fully Supported.

In a collision rich environment, Edgecam Advanced CNC Lathe will give you peace of mind when programming complex components. Optimize machining time with a full range of Turning and Milling Toolpath options available, Ensure you are getting the best Cycle time possible on your machine with full Turret Synchronization, and flexible Part transfer options.

Edgecam Ultimate CNC Lathe

Multi -Turret Twin Spindle Solution

Edgecam Ultimate CNC Lathe Module offers a Complete Turning Solution for Complex Multitask Machine Tools. Support for Up to 4 Turrets, dual Spindles and B axis Support. Full Turret Synchronisation to optimise Turret working time. Have peace of mind programming complex parts with full CNC machine Simulation and extensive toolpath functionality for all types of applications and tool types.

Wire EDM

Wire EDM

Software for Comprehensive Programming of all Wire EDM Machine Tools

Edgecam’s Wire EDM solution provides you with the flexibility and confidence to manufacture 2 and 4 axis parts accurately and efficiently. Advanced functionality enables manufacture of complex shapes with irregular tapers with ease. Extensive Post processors and Cutting technology databases.

Production Bundles

Essential Production

All round Solution for Milling machine Tools and 2 axis CNC Lathe centres

Edgecam Essential Production is the complete Solution comprised of the functionality of the Essential CNC Milling and Essential CNC Lathe Modules described. Program your 3 axis CNC Milling centres and 2 axis CNC Lathe/Turning centres with a cost effective Bundled CNC Software Solution.

– See Essential CNC Lathe and Essential CNC milling.

Standard Production

CNC Milling and CNC Lathe Software for programming your 3/4/5 Axis Machining centres and CNC Mill/Turn & CNC Lathe centres

Edgecam Standard Production is the complete Solution comprised of the functionality of the individual Standard CNC Milling and Standard CNC lathe Modules described. Program your 3/4/5 axis Machining centres and Mill/Turn Turning centres with a cost effective Bundled CNC Software Solution.

– See Standard CNC Lathe and Standard CNC milling.

Advanced Production

Advanced Machining Bundle for Multi Task CNC Lathe and up to 5 Axis Machining centres

Edgecam Advanced Production is the complete Solution comprised of the functionality of the individual Advanced CNC Milling and Advanced CNC Lathe Modules described. Program your 3/4/5 axis Machining centres and Multitask Turning centres with a cost effective Bundled CNC Software Solution.

– See Advanced CNC Lathe and Advanced CNC milling.

Ultimate Production

Penultimate Software for 5 axis Positional Machining centres and Multi Turret Multi-task CNC Mill/Turn Turning Centres

Edgecam Ultimate Production is the complete Solution comprised of the functionality of the individual Ultimate CNC Milling and Ultimate CNC Lathe Modules described. Program your 3/4/5 axis Machining centres and Multi Turret Multi task Turning centres with a cost effective Bundled CNC Software Solution.

– See Ultimate CNC Lathe and Ultimate CNC milling modules.

Add-On Modules

Solid Machinist

Standalone CAD Software interface and Knowledge based machining

Within Edgecam, the integrity of your design is maintained because any Native solid model from Mainstream CAD Software Vendors including Autodesk Inventor, Solidworks, Solid Edge, Creo, Unigraphics NX and CATIA to name a few, is imported without translation. Edgecam Solid Machinist uses automatic feature recognition to interrogate the solid model and quickly identifies machineable features to be machined. Edgecam then offers the user the most appropriate tooling and machining strategy to generate accurate toolpaths.

Building on this Solid foundation Edgecam Strategy Manager provides fast and reliable machining of solid models, resulting in increased productivity. The application streamlines programming by capturing the knowledge from previously machined parts and applying it to new components – eliminating programming errors and delivering an unprecedented level of consistency and automation.

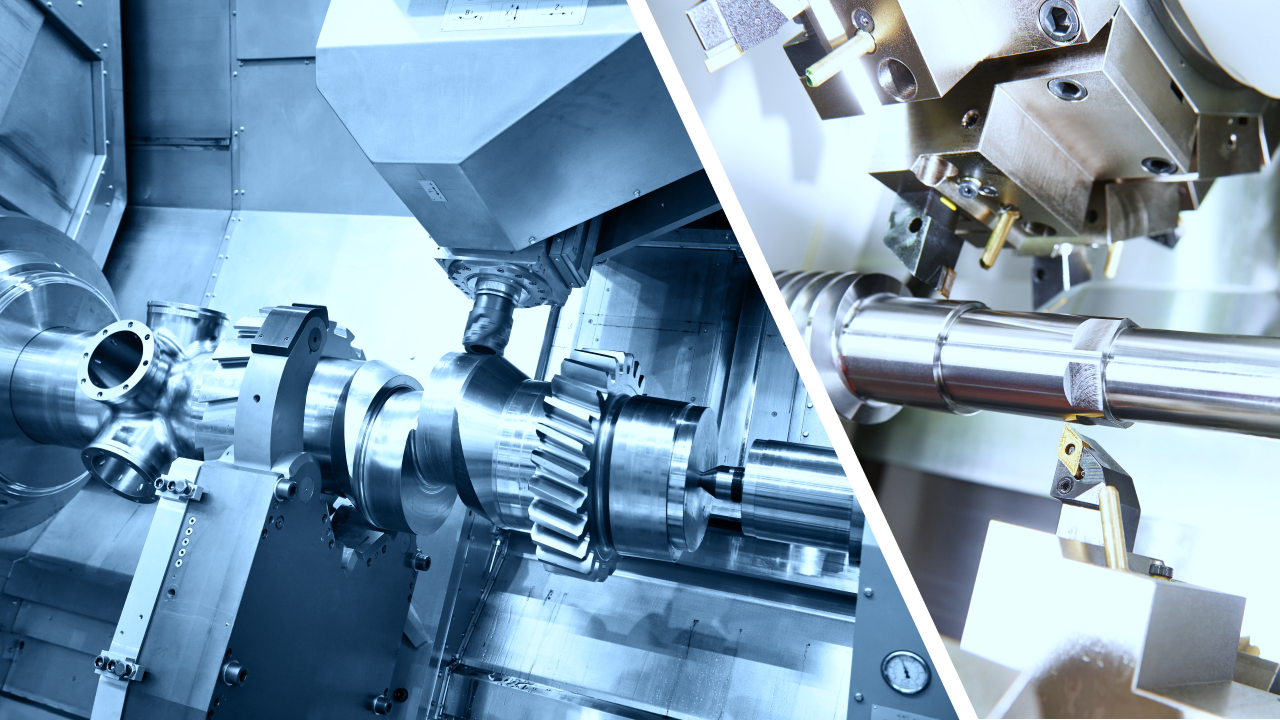

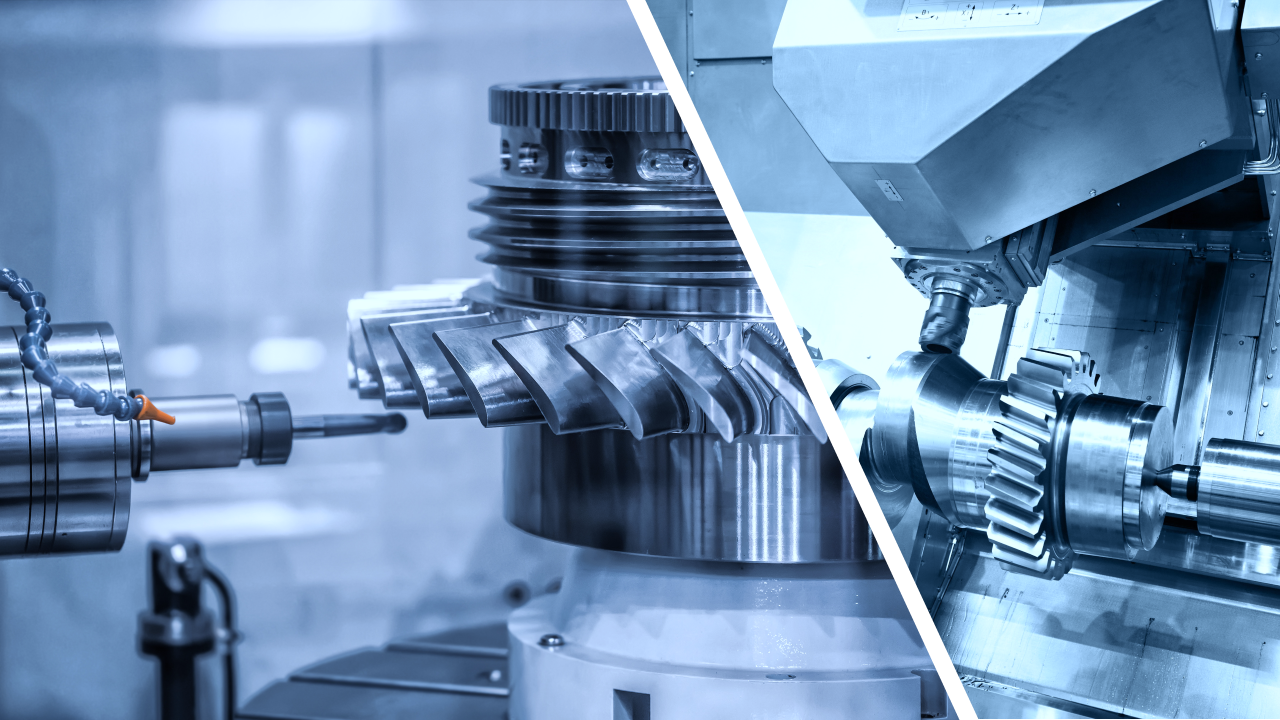

Edgecam 4 and 5 axis Machining

Software for full 4 and 5 axis Continuous Machining

Edgecam offers a wide range of 4 and 5 axis strategies applicable to solid and surface geometry.

Edgecam’s 4 axis strategies are ideal for the rotary machining of automotive and aerospace components such as camshafts, crankshafts and blades, as well as the production of rotary dies and components for the oil & gas industry.

With Edgecam 5 Axis Simultaneous, Improve Surface finish and extend tool life by by orientating tool to maintain optimum tool on part contact at all times. Improved access to undercuts and deep pockets – through tilting the tool or component and allows for shorter series tooling to be employed, eliminating the need for secondary setups. 5 axis tool paths can result in large movements of the machine tool from what can be a very small cut on the component. These movements can cause severe damage to the part and machine. Edgecam provides methods for collision avoidance where the cutter and holder are checked for collision and the necessary tilts applied to move away from the potential collision area.

Edgecam Advanced 5 Axis module provides total control of 4 and 5 axis tool paths using solids, surfaces or wireframe geometries. Advanced 5 Axis has additional functionality beyond the standard 5 axis and is ideal for more complicated components such as blings, blisks and port machining where tool path plus entry and exit path control with is of a very high importance.

Multiple Parts Machining- Tombstone Manager

Automate Tombstone Programming

Automate the entire Tombstone setup with capability of adding any number of components or any number of different components to the tombstone fixture. Maintain full toolpath associativity to the programmed single parts.

Advanced Multitask Machining

Software Solution for Rotating Turning Tools for Horizontal Machine Tools

Advanced Multi-Task gives you the ability to define and use Rotary Turning tools on large horizontal machine tools such as the Trevisan.

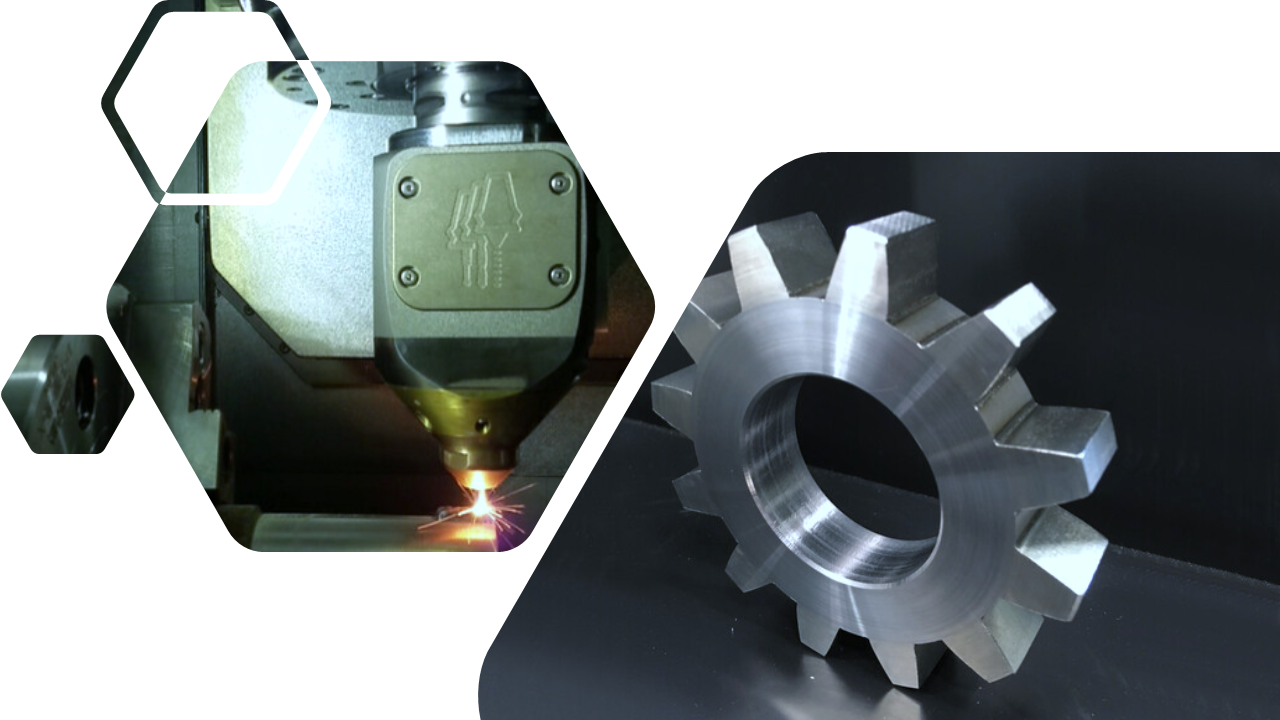

Additive and Hybrid Manufacturing

Additive Manufacturing Software for Hybrid Machine Tools

Edgecam Additive Module allows Companies adapt to new Hybrid Machine Tools where by an additive process of material deposition is layed down. A range of Cycles up to 5 axis allows companies to Add material and later Machine to size using the standard Machining process or commonly known today as subtractive, The combination of the processes allows Companies to fully utilize their machine tools with this capability.

Edgecam Probing and Inspection

Intelligent Software for On Machine Probing – Renishaw Part Probing

Edgecam Inspect combines industry leading metrology tools and know-how from Hexagon Manufacturing Intelligence with cutting edge manufacturing expertise from Vero Software. Edgecam Inspect is a full featured, easy to use solution for users wanting fast creation of on machine measurement cycles with quick, efficient tool path creation and generation of reliable, measurement results.

Edgecam Inspect is the ideal environment for the CAM programmer to develop machining and probing cycles in one output file. Because the inspection workflow is tightly integrated into the CAM workspace, the transition from machining to measuring and back again is seamless. Feedback is provided in the form of CMM style report templates along with graphical, colour coded deviation information that is displayed on the CAD model.

Update standard Work Offsets (G54-G59) in any X, Y and/or Z direction based on deviation from nominal. Change the protected position feedrate to minimise traverse time and reduce cycle time. Alter the search region of the probe to allow for flexible piece part positioning. Full probe and tool path simulation available as standard. No need to alter existing post processor

Renishaw: Will work with the following Renishaw Inspection Plus packages for Horizontal or Vertical Machining Centres (Note Inspection Plus cycles MUST be installed on the machine)

Specialist Systems

Inspection System

Standalone Inspection Software

Edgecam Inspect combines industry leading metrology tools and know-how from Hexagon Manufacturing Intelligence with cutting edge manufacturing expertise from Vero Software.

Edgecam Inspect is a full featured, easy to use solution for users wanting fast creation of on machine measurement cycles with quick, efficient tool path creation and generation of reliable, measurement results.

Shopfloor Editor

Just in time Program Editing

Edgecam Shop Floor Editor allows the machinist on the shop floor to load Edgecam part files, edit a limited number of parameters in the machining sequence, run Simulator and generate a new NC file.

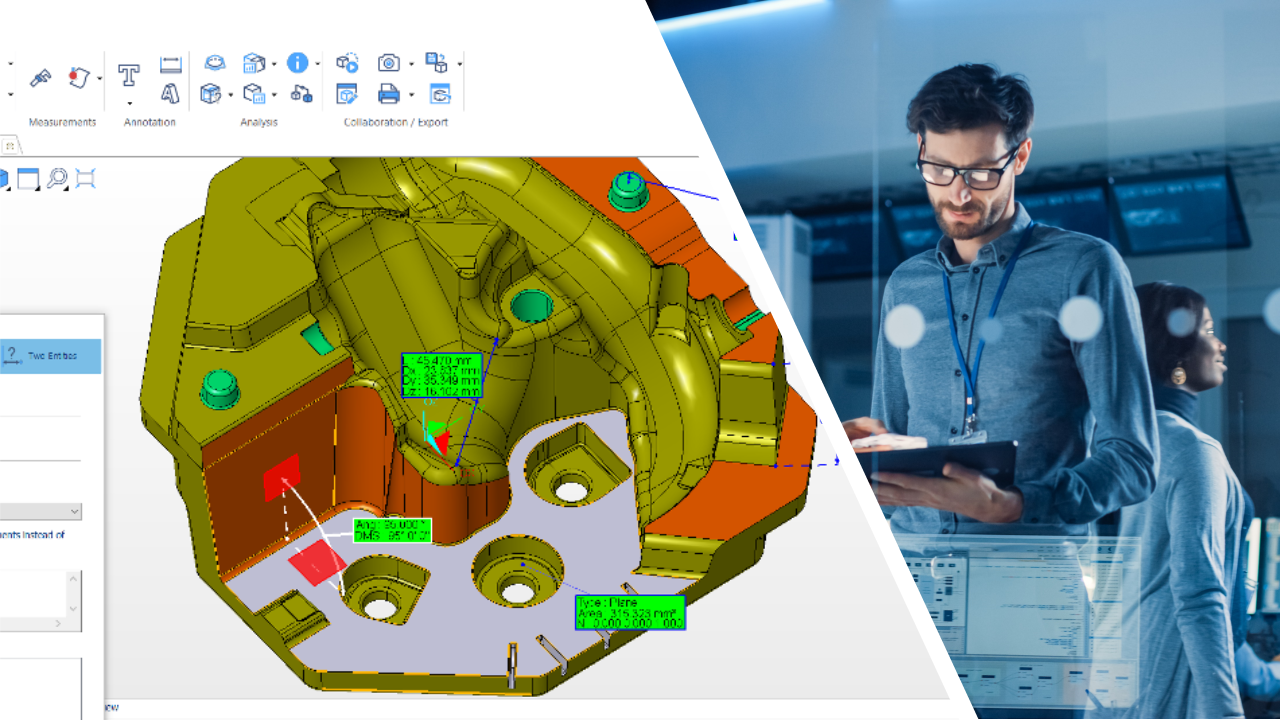

WorkXPlore

High Speed Collaborative CAD Viewer

WorkXplore is the ideal tool for directly displaying and evaluating 3D CAD Software files without the need for the original CAD Software application. The intuitive, easy to use interface enables novice and experienced users alike to explore and visualise any type of 2D/3D CAD Software file, analyse and finally Collaborate with others. This saves time before committing resources to creating a real prototype.

CONSULTING & SUPPORT

We consult with customers to find out where their capabilities lie and where they want to be. We are only too happy to meet with you and assist with obtaining your overall manufacturing effectiveness.

DEVELOPMENT

All Post processor development is carried out inhouse to ensure your requirements are met guaranteeing fast turnaround times.

TRAINING

We provide in depth training in our products for new customers from the get-go, and or for those users wanting to build on their knowledge in an ever-expanding Digital Manufacturing world, wanting to utilize their software investment to its fullest potential.

SPECIAL PROJCETS

We provide services to customers that require part programming for their CNC Machine tools or existing customers using our products looking to exploit more from their Software investment.

VIDEOS

Sign up to our Newsletter

Keep up to date with all our events and news by signing up to our newsletter.