Portable handheld scanners

- Portability

- Ease of use

- High performance

- Productivity boost

- Innovative technology

- Versatile

- Smart manufacturing integration

The easiest way to scan, whatever needs to be scanned

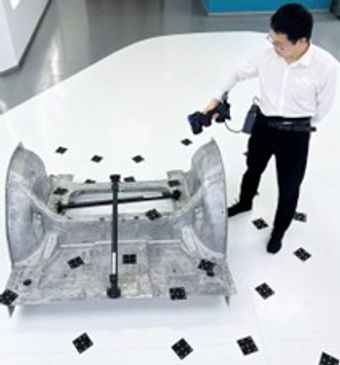

Handheld 3D scanners have become indispensable in modern manufacturing, valued for their portability, simplicity, and outstanding return on investment. Hexagon’s advanced range of handheld 3D scanners elevates these advantages even further—delivering precision, speed, and flexibility for both inspection and reverse engineering applications. From capturing complex geometries for digital re-creation to verifying production accuracy on the shop floor, these scanners provide high-quality data that streamlines processes and drives smarter manufacturing decisions. G-Zerofive proudly represents Hexagon as the local distributor, offering expert advice and support to help Australian manufacturers unlock the full potential of this innovative technology.

Design, offline CNC programming and G-code verification

Scanning - Portable, flexible and easy to use

Discover Hexagon’s Handheld 3D Scanners – ATLASCAN Max & MARVELSCAN

Experience the perfect blend of portability, precision, and performance. Hexagon’s latest handheld 3D scanners redefine what’s possible in digital measurement and data capture.

Backed by decades of innovation and trusted by industries worldwide, the ATLASCAN Max and MARVELSCAN deliver powerful, easy-to-use solutions for every scanning challenge. Whether you’re performing detailed inspections, reverse engineering complex components, creating rapid prototypes, or capturing large-scale environments, these scanners transform your workflow — turning every challenge into an opportunity for smarter, faster results.

ATLASCAN Max & MARVELSCAN

1. Complete Freedom of Movement

Unmatched portability and accessibility for every environment

With the ATLASCAN Max and MARVELSCAN, you’re no longer limited by cables, fixed setups, or line-of-sight constraints. Their lightweight, handheld design lets you scan directly at the part — even in confined or hard-to-reach spaces — without needing to move components to a quality room. The freedom to move anywhere and capture from any angle ensures effortless operation, faster results, and total flexibility across the shop floor or field.

2. Scan the Way You Need

Adaptive scanning for any part, surface, or condition

Whether the part is stationary or in motion, Hexagon’s handheld 3D scanners deliver high-accuracy results every time. Dynamic Scanning technology compensates for vibration and movement, making in-process measurement simple and reliable. MARVELSCAN’s built-in photogrammetry system eliminates the need for on-part targets — aligning scans automatically using background references — to reduce setup time, minimize errors, and keep your workflow efficient and uninterrupted.

3. Productivity Built In

Smart features that keep your workflow seamless

Optimized for real-world productivity, both scanners offer fingertip control to switch between scanning modes for large components, fine-detail features, or complex geometries. All captured data automatically merges into a single, unified point cloud or mesh for smooth downstream processing. Instant LED feedback ensures ideal scanning range at all times — helping you maintain quality, consistency, and speed from start to finish.

Smart solutions for real challenges

Instant visual feedback

Know you’re scanning correctly without returning to the control computer with built-in LED feedback system on the handset

Freedom of movement

Reach into hidden areas and cavities, get the right inspection angle without line-of-sight restrictions, scan at height, at distance, on the shop floor or in the field.

Galaxy mode

Thanks to the dual-camera system and built-in software algorithm, volumetric accuracy can be simply controlled by scanning the rectangle scale bar to allow quick changes during an inspection task .

Unstable measurement

Even challenging environment conditions with extreme noise and vibration are no problem for Dynamic Scanning.

3 Scan modes

Standard, Fine and Line scanning modes let you tailor your scanner performance to the application at hand, for greater efficiency or resolution as needed.

Change modes on-the-fly

Switch between scanning modes during measurement, directly from the handset, allowing you to fine-tune performance not just to the application but individual sections of the application.

Truly handheld scanning

Take the part in your hand and the scanner in the other for a very quick scan process that requires no complex part fixturing thanks to Dynamic Scanning.

Large standoff

Collect data from further away from the part, making it easier to access internal inspection areas such as tooling cavities, as well enabling automation system integration with lower collision risk.

Driving success through innovation and smart technology

Built-in photogrammetry

The MARVELSCAN boasts a unique photogrammetry system that powers its target-free scanning functionality, and allows for standalone photogrammetry inspection.

Hole Flash Capture technology

Rapid simultaneous inspection of multiple circular and slotted features speeds up the workflow for a key industrial inspection challenge.

Multi-size target recognition

Maximise efficiency by using different target sizes (3/6/12 /16mm) for different applications during the scanning process .

Lightweight ergonomic design

Fits perfectly in the hand and light enough to take anywhere and use comfortably for long inspection projects.

Combine scanning mode results

Data collected with different scanning modes is seamlessly combined within the same point- cloud/mesh for ease of analysis and reporting.

Wireless Scanning Module

Set yourself free from movement limiting cables and referencing hardware with the option of full wireless functionality.

Automation ready

Both the ATLASCAN Max and MARVELSCAN are ready for straightforward third-party integration within automated inspection systems.

Large standoff

Collect data from further away from the part, making it easier to access internal inspection areas such as tooling cavities, as well enabling automation system integration with lower collision risk.

VDI/VDE certification

Results are certified in line with the VDI/VDE 2634-3 to assure reliability and comparability of measurement.

The patented MARVELSCAN solution. 3-in-1 workflow

3D scanning

Target-free 3D scanning

Target-free 3D scanning

Using on-part targets, MARVELSCAN allows for high-productivity 3D scanning inspection, including Dynamic Scanning of unfixtured objects.

Target-free 3D scanning

Target-free 3D scanning

Target-free 3D scanning

With its built-in photogrammetry system, the MARVELSCAN can inspect with no need for targets placed on the part by using a specially installed target wall for referencing.

Photogrammetry

Target-free 3D scanning

Photogrammetry

By using the MARVELSCAN’s photogrammetry system as a standalone photogrammetry tool to augment 3D scanning, measurement accuracy is significantly increased for larger parts.

Contact Us

G ZEROFIVE Pty Ltd

Copyright © 2025 G Zero Five - ABN 84 133 541 581 | All Rights Reserved.

Copyright © 2025 G Zero Five - ABN 84 133 541 581