EDGECAM

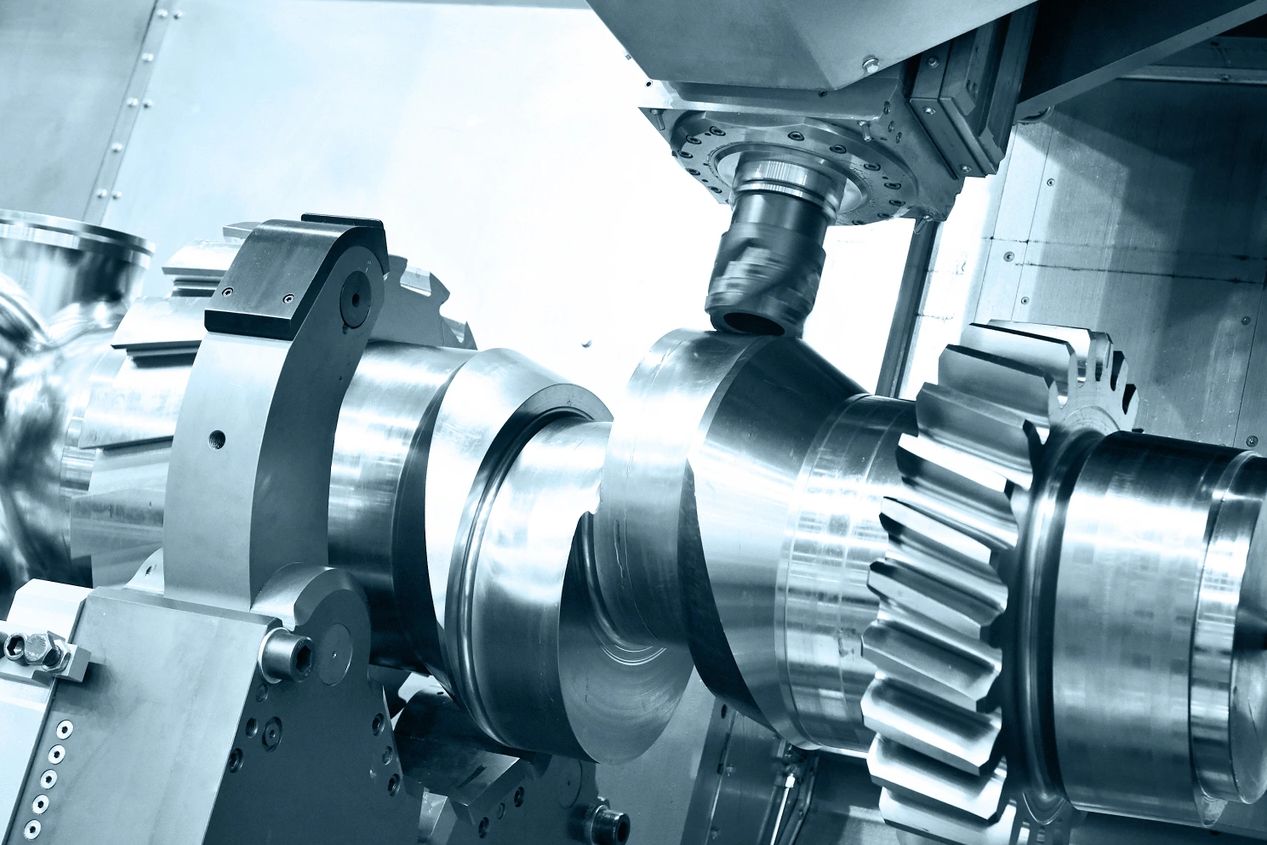

CAD Neutral functionality makes this CAM software easy to use, supporting complex machine operations like Wire EDM. With its robust CNC programming capabilities, it also facilitates hybrid manufacturing and production machining programming, along with efficient probing and inspection features.

Our design, scanning & Virtual machine simulation solutions

NCSIMUL Machine

Handheld portable scanners

NCSIMUL Machine

CNC programming involves the validation and simulation of CNC G-code programs, a critical aspect often enhanced by CAM software, particularly with the advanced features of EDGECAM.

Handheld portable scanners

Handheld portable scanners

Handheld portable scanners

Reverse engineer or inspect components using advanced CAM software, which enhances CNC programming capabilities and showcases unique EDGECAM features.

EDGECAM in a nutshell

Transform your machining workflow — explore EDGECAM

From simple parts to complex components — explore what EDGECAM can do.

Offline CNC Programming Solutions

EDGECAM Milling

EDGECAM Wire EDM

EDGECAM Milling

EDGECAM Turning

EDGECAM Wire EDM

EDGECAM Milling

EDGECAM Wire EDM

EDGECAM Wire EDM

Production systems

Production systems

Automated programming

Production systems

Inspection

Automated programming

Automated programming

Automated programming

Automated programming

Automated programming

EDGECAM - Advanced CAM for Production machining

Features at a glance

Edgecam seamlessly integrates with mainstream CAD software, such as Solidworks, Autodesk Inventor, Solid Edge, and Creo, functioning as a standalone CAM software solution. It offers users an easy-to-use graphical interface and intuitive dialogues, making CNC programming simple for first-time users while providing full control for advanced tool path requirements.

Comprehensive support is available for 2.5 Axis to full 5 Axis simultaneous milling. Complex mill/turn components and machine tools are easily managed, with full support ranging from 2 Axis turning to advanced multiple turret systems, B Axis with twin spindle support, and up to 6 axis machining centers. Edgecam's wire EDM CAM solution gives you the flexibility and confidence to manufacture 2 and 4 axis parts accurately and efficiently. Complete your workflow with on-machine measuring using Edgecam's probing and inspection functionality.

EDGECAM described in 3 minutes

A range of standard Edgecam options available

Standard in all EDGECAM products

Add on modules and specialist systems

Add on modules and specialist systems

Multiple setups for different machining operations can be easily managed on the same machine tool or across various machining disciplines using advanced CAM software. Automatic feeds and speeds calculation comes standard with comprehensive tooling libraries, enhancing the efficiency of CNC programming. The system features full dynamic stock management, along with tool, holder, and fixture collision avoidance to ensure safe operations. Edgecam eliminates 'fresh air cutting' by recognizing the latest stock condition after each machining process, only machining areas where stock from previously un-machined regions is necessary. With full machine simulation and collision detection, users can automate programming through Edgecam PCI Macros and templates or leverage Edgecam’s knowledge-based manufacturing strategies for 3D solids-based programming. Additionally, shop floor documentation of the operation process is automatically generated, including a tooling kit and list.

Add on modules and specialist systems

Add on modules and specialist systems

Add on modules and specialist systems

Unlock the Full Power of EDGECAM with Add-On Modules

Enhance productivity and precision with EDGECAM’s optional modules designed to automate CNC programming and reduce setup time. Each module extends capability—whether it’s advanced 5-axis machining, mill-turn, or feature recognition. These EDGECAM features give you the confidence to take on more complex jobs. Scalable and flexible, EDGECAM grows with your business, delivering faster programming, consistent quality, and maximum machine utilization for a smarter, more profitable workshop.

Post Processing

EDGECAM CAM Software

Benefits of Locally Developed EDGECAM Post Processors

Precision-Matched to Each Customer’s Requirements

Every post processor is developed and tested specifically for your machines, tooling, and control configuration within our CAM software — ensuring output that matches your exact manufacturing process. This eliminates time spent manually editing NC code in CNC programming and guarantees consistent, accurate results straight from EDGECAM.

Developed and Tested for the Australian Market

All post development and validation are performed locally, with a comprehensive understanding of Australian machining standards, common machine tool brands, and shop floor practices. This ensures better alignment with regional needs and faster support turnaround, showcasing the key EDGECAM features that benefit local businesses.

Seamless Integration and Reliability

Our posts are built using proven templates and tested in real machining environments to deliver reliable, error-free NC output — reducing downtime and improving production flow, which is essential for effective CNC programming.

Local Support and Continuous Improvement

Having all development done in Australia means direct access to the technical team that built your post. Updates, modifications, and fine-tuning are handled quickly, ensuring your post evolves with your business and the capabilities of our CAM software.

Enhanced Productivity and Confidence

With a post tailored to your machines and proven in your conditions, programmers and operators can trust the code — focusing on optimizing toolpaths, not troubleshooting NC output.

EDGECAM Milling Systems

Essential Milling

2.5 Axis Milling

Ideal for companies utilizing 3 axis machining centers, 2.5 axis milling is perfect for components that don't require the full capabilities of 3 axis CNC programming. Edgecam's CAM software offers a comprehensive range of milling and drilling options to expedite the programming of those parts. With the Edgecam CAM Simulator, visualize the entire machining process through full machine simulation, ensuring efficient part machining while reducing setup time and tooling costs.

Explore our add-on modules to maximize the potential of your system, including Solid Machinist and Strategy Manager, along with probing capabilities.

Standard Milling

Experience full 3-axis capabilities with a 4th axis rotary and positional feature, alongside 5-axis positional capability, all optimized for your machining needs. This setup is ideal for both vertical and horizontal 4 or 5 axis machining centers. The Edgecam module is the leading choice to maximize the efficiency of your machine tool from the start. With a comprehensive suite of hole options, Edgecam’s effective Waveform Roughing strategies and 3-axis finishing toolpaths enhance productivity through single setups on 4/5 axis CNC machines, showcasing the impressive capabilities of this CAM software.

Upgrade your CNC programming with add-on modules to further enhance your system, including Solid Machinist and Strategy Manager, automatic multiple parts setup, 4-axis simultaneous machining, and probing and inspection features.

Advanced Milling

Support for angled head attachments and secondary Z/Quill axis enhances the capabilities of your CAM software. By adding to the 3-axis functionality of the standard CNC milling module, Edgecam Advanced CNC milling includes robust features such as deep hole drilling, plunge roughing, and a wider range of 3-axis surface/free-form finishing toolpaths. Additionally, this CNC programming solution supports more advanced machine configurations, such as angle head attachments and quill axis.

To maximize your system's potential, consider add-on modules like Solid Machinist and Strategy Manager, which offer automatic multiple parts setup, 4/5 axis simultaneous machining, and probing and inspection.

Ultimate Milling

Explore the complete suite of Edgecam features for surface finishing toolpaths. By leveraging the advanced capabilities of the CAM software and the Advanced CNC Milling Module, you can access Edgecam’s outstanding Mold & Die 3-axis finishing cycles to achieve optimal surface finishes on freeform components.

Enhance your CNC programming experience with add-on modules that maximize your system’s potential. Utilize Solid Machinist and Strategy Manager for automatic multiple parts setup, as well as 4/5 axis simultaneous machining, probing, and inspection.

EDGECAM Turning Systems

Essential Turning

2 Axis Turning is ideal for CNC programming on both 2 Axis Vertical and Horizontal CNC lathes equipped with a Single Turret and Single Spindle. The system includes tailstock and steady rest support for all tool types, enhancing the versatility of your machining capabilities. With advanced functionality for all 2 axis turning applications, whether dealing with large or small components, hard or soft materials, Edgecam provides powerful CAM software that gives you complete control over the production process. The full machine simulation feature in the Edgecam CAM Simulator helps you avoid unwanted collisions and reduces setup time.

To further enhance your experience, add-on modules are available to maximize the benefits of your system, including Solid Machinist and Strategy Manager, which leverage EDGECAM features for efficient CNC programming.

Standard Turning

The 2 axis CNC Lathe with CY axis Milling Capability is designed to enhance CNC programming for both Vertical and Horizontal CNC Lathe Centres, including Single Spindle and Single Turret Machines with Live Tooling / Milling Capability. With this CAM software, you can machine components that were previously difficult to achieve due to limited programming capabilities at the machine control. EDGECAM features, such as the Standard CNC Lathe Module, provide the ability to machine complex components using advanced and efficient toolpaths, including Edgecam Waveform Turning technology, which helps save on machine time, setup time, and tooling costs.

Enhance your system with add-on modules like Solid Machinist and Strategy Manager, as well as Probing and Inspection.

Advanced Turning

Designed for Turn/Mill Multi-Task Machine Tools, our CAM software offers robust support for twin turret and single or twin spindle CNC machines. Machines equipped with B axis capability are fully supported, ensuring top performance.

In a collision-rich environment, the Edgecam Advanced CNC Programming solution provides peace of mind when programming complex components. Optimize your machining time with a comprehensive range of Turning and Milling Toolpath options available. Ensure you achieve the best cycle time possible on your machine with complete Turret Synchronization and flexible part transfer options.

Enhance your experience with add-on modules to maximize the capabilities of your system, including Solid Machinist and Strategy Manager, as well as support for 4/5 Axis simultaneous machining, probing, and inspection, all featuring the powerful EDGECAM features.

Ultimate Turning

Multi-Turret Twin Spindle Solution.

The Edgecam Ultimate CNC Lathe Module provides a comprehensive CNC programming solution for complex multitask machine tools. This powerful CAM software supports up to 4 turrets, dual spindles, and B-axis support. With full turret synchronization, you can optimize turret working time effectively. Enjoy the peace of mind that comes with programming intricate parts using full CNC machine simulation and extensive toolpath functionality suited for all types of applications and tool types.

Enhance your system with add-on modules.

Explore features like Solid Machinist and Strategy Manager, along with support for 4/5 axis simultaneous machining, probing, and inspection.

EDGECAM WIRE EDM

Wire EDM

Software for Comprehensive CNC Programming of all Wire EDM Machine Tools.

Edgecam’s CAM Software for Wire EDM provides you with the flexibility and confidence to manufacture 2 and 4 axis parts accurately and efficiently. Its advanced EDGECAM features enable the manufacture of complex shapes with irregular tapers with ease, supported by extensive post processors and cutting technology databases.

Explore add-on modules like Solid Machinist and Strategy Manager to maximize the capabilities of your system.

EDGECAM Production Systems

Essential Production

All-round Solution for Milling Machine Tools and 2 Axis CNC Lathe Centres

Edgecam Essential Production is the complete CAM software solution that encompasses the functionality of the Essential CNC Milling and Essential CNC Lathe Modules described. Program your 3 Axis CNC Milling centres and 2 Axis CNC Lathe/Turning centres with a cost-effective Bundled CNC Programming Solution.

– See Essential Turning and Essential Milling functionality above.

Enhance your experience with add-on modules to get more out of your system, including Solid Machinist and Strategy Manager, along with Probing options to maximize the benefits of EDGECAM features.

Standard Production

CNC Milling and CNC Lathe Software for programming your 3/4/5 Axis Machining centres and CNC Mill/Turn & CNC Lathe centres using advanced CAM Software.

Edgecam Standard Production is the complete solution that integrates the functionality of the individual Standard CNC Milling and Standard CNC Lathe modules. Utilize this powerful CNC Programming tool to program your 3/4/5 axis Machining centres and Mill/Turn Turning centres with a cost-effective bundled CNC Software solution.

– Explore the Standard Turning and Standard Milling functionality above, highlighting key EDGECAM features.

Enhance your system further with add-on modules like Solid Machinist and Strategy Manager, automatic multiple parts setup, 4-axis simultaneous machining, as well as Probing and Inspection options.

Advanced Production

Advanced Machining Bundle for Multi Task CNC Lathe and up to 5 Axis Machining Centres

Edgecam Advanced Production is the complete CAM Software solution that includes the functionalities of the individual Advanced CNC Milling and Advanced CNC Lathe Modules described. Program your 3/4/5 axis Machining centres and Multitask Turning centres with this cost-effective Bundled CNC Programming solution.

– See Advanced Turning and Advanced Milling functionality above.

Enhance your system with add-on modules to maximize your capabilities with Solid Machinist and Strategy Manager, Automatic multiple parts setup, 4/5 Axis Simultaneous machining and Probing and inspection modules.

Ultimate Production

Penultimate CAM Software for 5 axis Positional Machining centres and Multi Turret Multi-task CNC Mill/Turn Turning Centres

Edgecam Ultimate Production is the complete solution that integrates the functionality of the individual EDGECAM features, including Ultimate CNC Milling and Ultimate CNC Lathe Modules. Efficiently program your 3/4/5 axis machining centres and Multi Turret Multi-task turning centres with this cost-effective bundled CNC programming solution.

– Explore Ultimate Turning and Ultimate Milling functionality above.

Enhance your system with add-on modules by adding Solid Machinist and Strategy Manager, Automatic multiple parts setup, 4/5 Axis simultaneous machining as well as Probing and inspection

Our design, scanning & Virtual machine simulation solutions

DESIGNER

Handheld scanners

DESIGNER

True CAD for CAM software enhances CNC programming capabilities with features like direct modeling, easy model repair, advanced surfacing, and electrode design. Additionally, it supports reverse engineering and sheet metal design, making it a comprehensive solution that showcases various EDGECAM features.

NCSIMUL

Handheld scanners

DESIGNER

CAM Software features a neutral format, enabling the creation of a real CNC 'Digital Twin.' With advanced CNC programming capabilities, users can achieve fast G-code validation and precise G-code simulation. Additionally, tools for tool length optimization and toolpath optimization are integral to enhancing efficiency in lights out manufacturing.

Handheld scanners

Handheld scanners

Handheld scanners

Portability and ease of use are key aspects of CAM software, designed to enhance CNC programming efficiency. With high performance and innovative technology, this software provides a significant productivity boost. Its versatility allows for smooth integration into smart manufacturing processes, utilizing EDGECAM features to streamline operations.

Check out EDGECAM in 3 minutes

Your machining advantage starts here — EDGECAM in 3 minutes.

Contact Us

G-ZEROFIVE Pty Ltd

Copyright © 2025 G Zero Five - ABN 84 133 541 581 | All Rights Reserved.

Copyright © 2025 G Zero Five - ABN 84 133 541 581